Technology

- COR >

- Technology

Made by injection molding

To save weight and meet modern fuel efficiency standards, automotive engineers have learned to substitute plastic materials for metal wherever possible. Even beyond weight savings, versatile plastics offer numerous manufacturing efficiencies.

Compared to machining or die-casting, rapid, cost-saving material processing methods such as short cycle-time injection molding allow high-volume production, often with no secondary steps. Nonetheless, many automotive parts are made from metal. The applicative temperature and dimensional demands are often the deciding factors in terms of material chosen.

New developments in high dimensionally and thermally stable polymer resins and molding tooling techniques have however shifted the balance of suitable materials; they have expanded the range of applications for which polymer materials may be used.

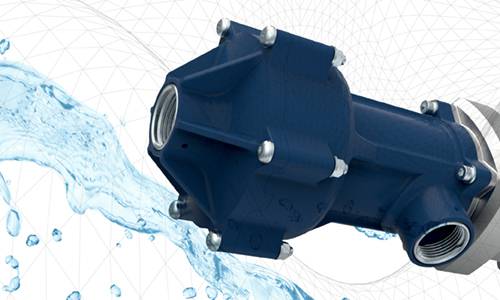

COR pump technology is an excellent example of an automotive component, which is now amenable to be made from a high dimensionally and thermally stable polymer material. Such approach allows to mould the most demanding components with a reasonable accuracy.